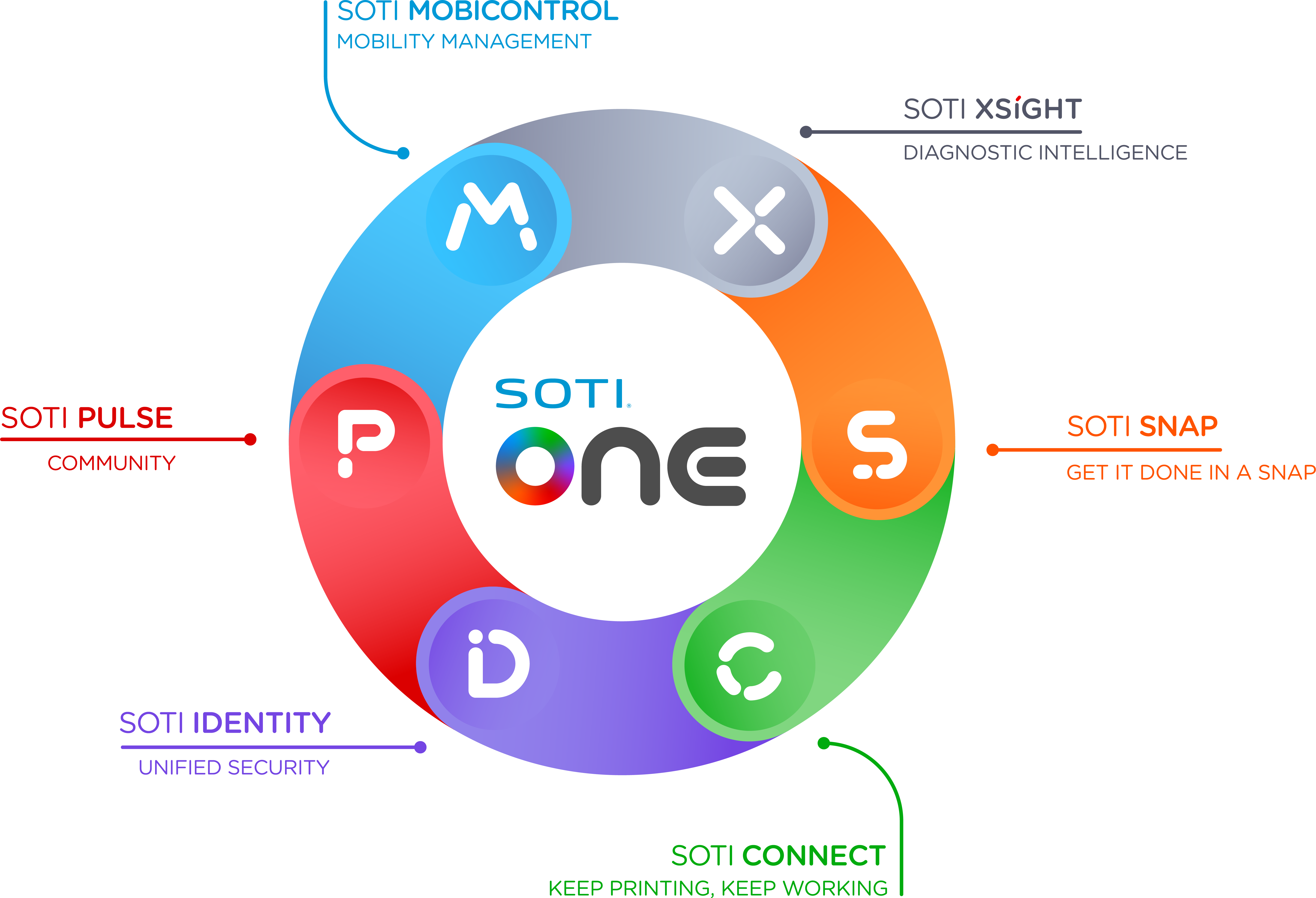

Logistics Provider Cuts Battery Replacement Costs by 50% with SOTI MobiControl XS

-

Transportation & Logistics

-

Battery Usage Dashboard, Data Usage Dashboard,

Signal Strength Dashboard

-

Tablets

-

Android

-

North America

This leading logistics provider serves customers across North America and handles over one million packages daily. The company has thousands of employees and more than 1,000 authorized shipping agents across multiple locations. With a fleet size of over 3,000 vehicles and hundreds of shipping centers and drop boxes, operations must run smoothly to meet consumer needs.

The Challenge

The company faced challenges with battery-related downtime, as it had no visibility into battery health. It unnecessarily replaced entire battery fleets every 12-15 months, which increased operational expenses significantly. Additionally, the company invested in core business apps but lacked visibility into usage. Its IT team was unable to determine whether these business apps were draining device batteries excessively or being used effectively. Ultimately, it could not measure the ROI of these apps.

The company also had no visibility into cellular coverage, which is crucial to ensure drivers can process deliveries and access route information. These challenges introduced the risk of missed deliveries and fines that needed to be minimized.

The Solution

The implementation of SOTI MobiControl XS provided a comprehensive solution to address each business problem. With the Battery Dashboards, the company has an overview of key battery health indicators. It can determine which batteries will last an entire shift and when to replace unhealthy ones.

The App Usage Dashboard enables the company to determine which business apps are used and for how long during a shift. This has optimized app deployment and provided the opportunity to measure the relative battery efficiency of different apps.

Finally, with the Signal Strength Dashboard, the company can now identify dead/low signal strength via heat maps that show signal coverage reported through devices. This has improved network connectivity across its operations. These tools offer real-time insights and control, enabling data-driven decision-making and operational improvements.

The Results

As a result of the Battery Dashboards, the company reduced its battery replacement costs by 50% ($500K per year). With the insights gained from the App Usage Dashboard, it improved app utilization and increased the productivity of its workforce. Lastly, the Signal Strength Dashboard led to a 15% improvement in network coverage because of carrier optimization.